06-24-2016, 04:15 PM

Gidday Wayne as I was only looking for information on the car, and also because ignorance is bliss, I didn’t take much notice of the other pages in this link. (I presume that the links work for others)

<!-- m --><a class="postlink" href="http://gathpast.tripod.com/tour1.html">http://gathpast.tripod.com/tour1.html</a><!-- m -->

Now there is I believe a discrepancy in some of the captions at the very least, because they refer to the photo of the car as taken in the late thirties, whereas CISX 500 has the build date of 10 41.

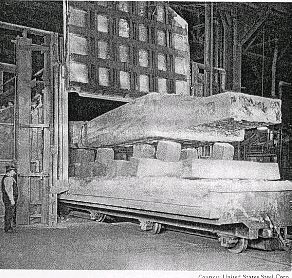

However this photo, and I’m not sure how it will reproduce shows, I presume, one of the ingots from G11 mould, (there’s a photo showing an identical G13 mould) starting a process. The bloke standing at the left gives scale.

The caption reads, This picture shows a large ingot which is about to be reheated for strength. This steel is about to be turned into armour for use in the Second World War. The idea is to take the steel with the lowest possible amount of impurities, and reheat it in manners which strengthen the metal. This ingot was used in the production of tanks or ships. The finished metal would be rolled into armour.

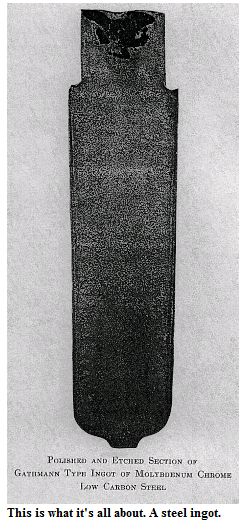

Polished and etched section of Gathmann type ingot of Molybdenum Chrome Low Carbon Steel.

As I have stated I wouldn’t know what standard practise was in the steel industry if it bit me on the leg, but hopefully this makes sense to you.

Cheers, the Bear.

Edit, I see Marks posted while I've been writing.

<!-- m --><a class="postlink" href="http://gathpast.tripod.com/tour1.html">http://gathpast.tripod.com/tour1.html</a><!-- m -->

Now there is I believe a discrepancy in some of the captions at the very least, because they refer to the photo of the car as taken in the late thirties, whereas CISX 500 has the build date of 10 41.

However this photo, and I’m not sure how it will reproduce shows, I presume, one of the ingots from G11 mould, (there’s a photo showing an identical G13 mould) starting a process. The bloke standing at the left gives scale.

The caption reads, This picture shows a large ingot which is about to be reheated for strength. This steel is about to be turned into armour for use in the Second World War. The idea is to take the steel with the lowest possible amount of impurities, and reheat it in manners which strengthen the metal. This ingot was used in the production of tanks or ships. The finished metal would be rolled into armour.

Polished and etched section of Gathmann type ingot of Molybdenum Chrome Low Carbon Steel.

As I have stated I wouldn’t know what standard practise was in the steel industry if it bit me on the leg, but hopefully this makes sense to you.

Cheers, the Bear.

Edit, I see Marks posted while I've been writing.

"One difference between pessimists and optimists is that while pessimists are more often right, optimists have far more fun."