08-26-2024, 05:22 PM

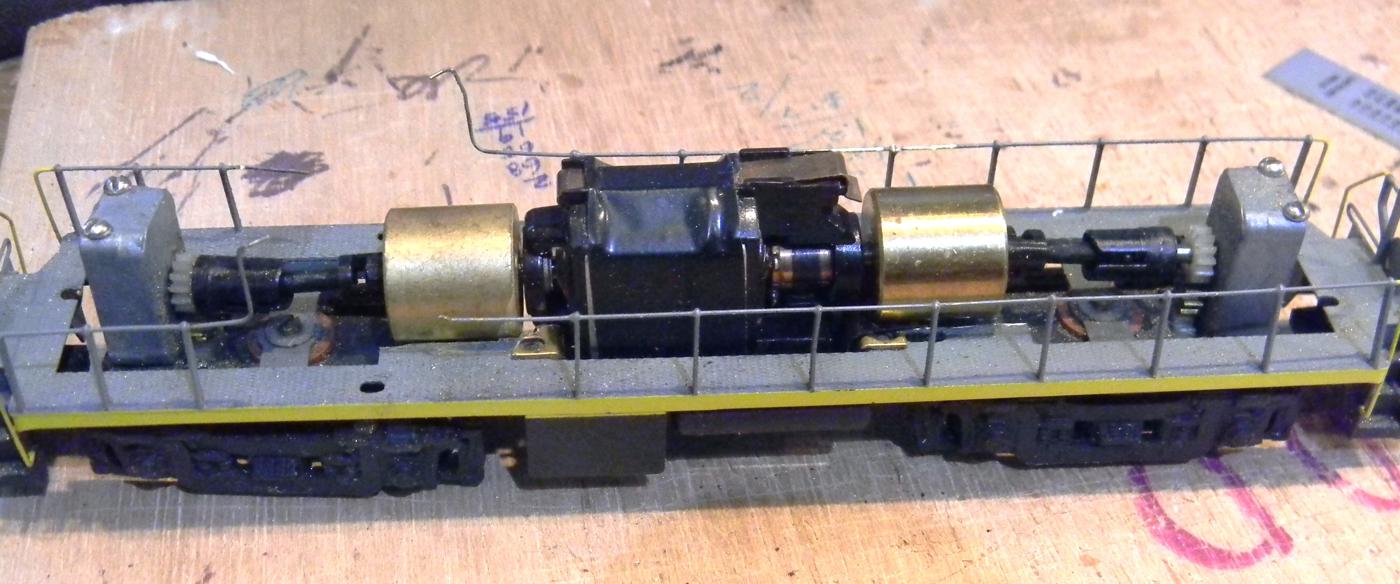

Measured up the steel gearshafts - 0.093" according to a set of calipers and found a bit of the same size. Ended up putting it in the chuck of a drill press, but rather than turn on the motor, I just twisted the plastic knuckles up onto the bit through the smaller hole to take away the extra material. Nice friction fit when all was said and done. When I came home from work today I got the cutting wheel back out and took the extra length off of the forward shaft and inserted both knuckles on the front and rear shafts and slid in the motor with the shafts connected. Looks like a nice fit to me in terms of longitudinal slop and ability to move the locomotive through a curve and maintain power to the gearing, but I still see some impingement between the flywheels and the chassis that I'll have to address before adding the DCC decoder. As NASA would say, everything's looking good for eventual launch.

Check out my "Rainbows in the Gorge" website: http://morristhemoosetm.wixsite.com/rainbows