07-09-2009, 09:53 AM

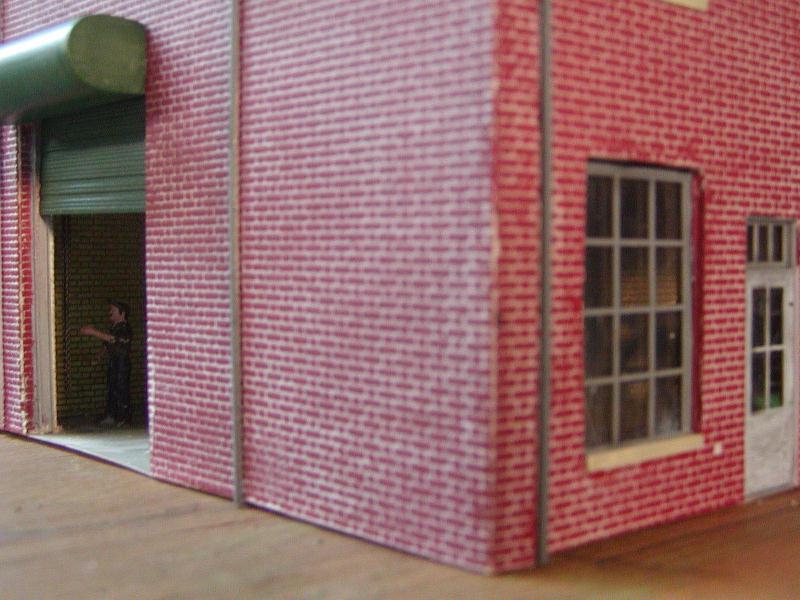

Hi Wayne, I'm back from my short trip. I do have some of the old Holgate and Reynolds material, which is vinyl. But I was planning on using the styrene brick sheet by Model Builders Supply Line, part of N Scale Architect. I believe when you were here you took a close look at the Quinn Ball Bearing plant. It uses the Holgate and Reynolds material. The powerhouse on the other hand uses the Model Builders styrene sheet. The pic below show a couple corners on the powerhouse. Note the sharp corner by the loading door split when formed, as you might expect. The corner of the building did not, but is a bit rounded, not a tight 90 degree corner. This seems to be the dilema of using styrene versus the vinyl. However, I experimented and it seems possible to get a tighter corner with styrene by heating the styrene with a hair dryer. Before I went away I cut a piece of the vinyl material and bent it to 90 degrees, and heated a bit of the styrene material with the hair dryer, and bent it to 90 degrees. I used Barge cement to attach both pieces to a piece of wood. Barge cement is basically a contact cement, I think. I bought and use it for glueing rail to both plastic and wood ties. I have never (over several years) had any gauge problems with track laid this way. So I thought I'd give it a try. Upon coming home four days later, both the vinyl and styrene brick are securely attached, and the styrene was not affected adversely. The heated styrene sems to have tken the 90 degree bend well. For reasons of ideal material consumption, I would love to use the vinyl material for the "basement" walls as shown earlier, and styrene for the main bldg, as I would not need to buy more of either. However, the size of the bricks depicted by the two products are very different, leading me to believe I should not do so. You can see the size difference in the pic below, I quicly brushed on some thinned black paint to make the brick sizes more evident. Do you agree the difference is too stark?