03-16-2012, 08:51 AM

I have read many articles on power routing Peco 'electrofrog' turnouts for DCC, but for my situation, I don't beleive it is necessary.

Situation;

1. All turnouts will be Peco code 55 electrofrog,

2. The spring will be left in using servos for a 'motor' (I don't care about slow motion or the 'snap' sound),

3. No reverse loops or 'wyes',

4. Layout will be DC for now, but wired for DCC (insulated joiners both rails and all four exit rails on each turnout insulated),

5. I plan on using NoOx to get a handle on track cleaning after reading many articles on it's benefits,

6. No steam, all diesels (if that matters).

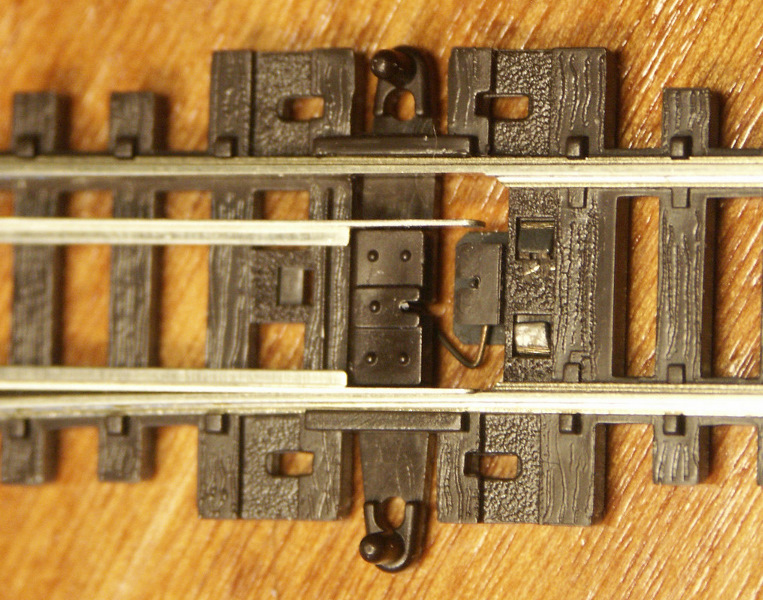

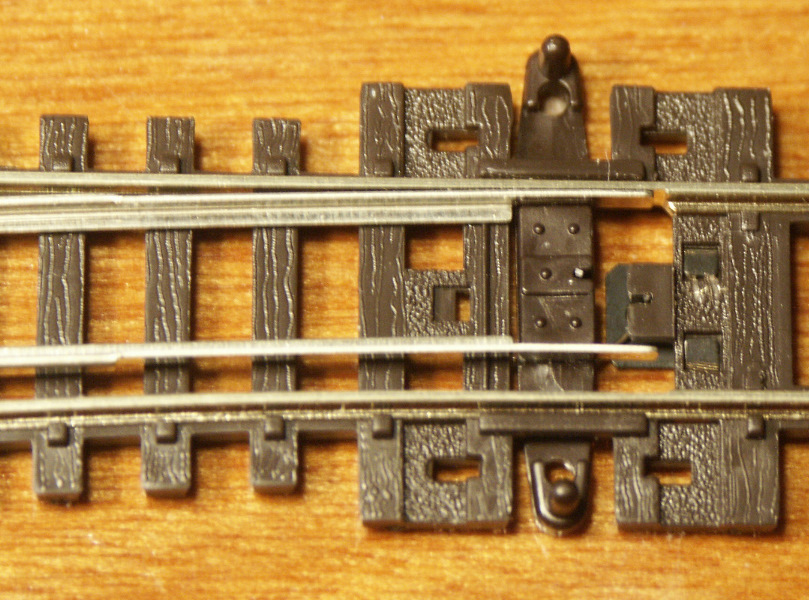

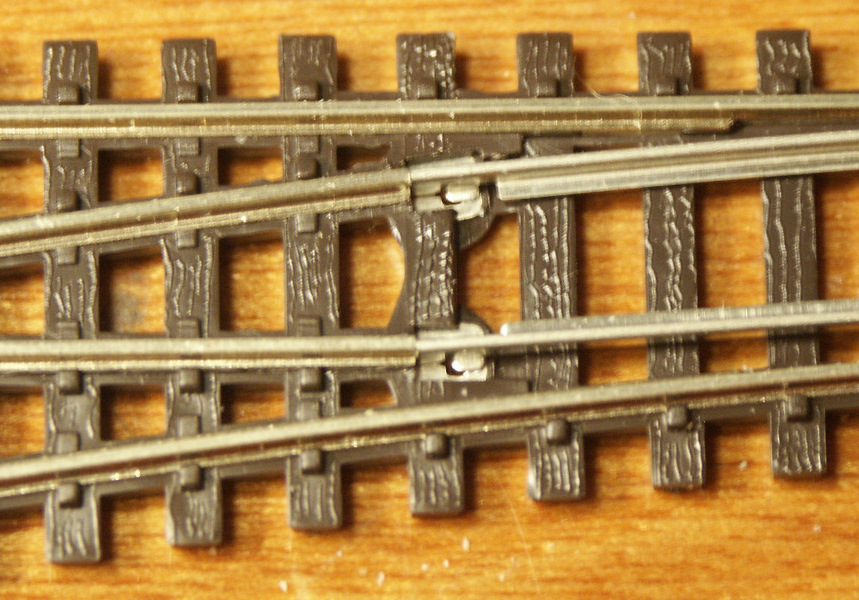

I'm concerned about long term contact problems with oxidation between the points and the stock rails. Mostly for the curved point since the straight point has considerably more contact area. Also, the 'hinge' area between the points and the closure rails. I know it is recommended to cut the closure rails, but I don't want to do this as long as there won't be a contact problem with the points down the road (no pun intended).

See the attachments.

I have read up on this NoOx which has been out for decades and it appears to be the 'cats meow' for oxidation problems and keeping the rail clean better than any track cleaner car etc. Will NoOx help solve the problem?

Situation;

1. All turnouts will be Peco code 55 electrofrog,

2. The spring will be left in using servos for a 'motor' (I don't care about slow motion or the 'snap' sound),

3. No reverse loops or 'wyes',

4. Layout will be DC for now, but wired for DCC (insulated joiners both rails and all four exit rails on each turnout insulated),

5. I plan on using NoOx to get a handle on track cleaning after reading many articles on it's benefits,

6. No steam, all diesels (if that matters).

I'm concerned about long term contact problems with oxidation between the points and the stock rails. Mostly for the curved point since the straight point has considerably more contact area. Also, the 'hinge' area between the points and the closure rails. I know it is recommended to cut the closure rails, but I don't want to do this as long as there won't be a contact problem with the points down the road (no pun intended).

See the attachments.

I have read up on this NoOx which has been out for decades and it appears to be the 'cats meow' for oxidation problems and keeping the rail clean better than any track cleaner car etc. Will NoOx help solve the problem?