07-29-2009, 10:25 PM

I thought that I had moved this here earlier, but I can't seem to locate it.

Rather than buying cast brass lagged pipe, you can make you own easily and at low cost, too. I made my pipe to represent a steam supply line for a Barber-Green Snow Loader.

First, fabricate the pipe from suitably-sized brass wire: use wire about two scale inches or so smaller in diameter than what you require for a finished size. The one shown below is .052", which is about 4 1/2" in HO. Make all of the necessary bends and determine the method that you'll be using to fasten it in place before starting the actual lagging procedure.

For lagging, stick a length of ordinary masking tape to a sheet of glass, then, using a new blade, trim off the factory edges and discard them. Next, measure and mark for the width of lagging that you want to use: for my large pipe, I made it 1'(HO) wide, and for the 4" (actual) length of the pipe, I used about 16" (actual) of tape.

Start at an end, or, as I did, at one of the mounting fixtures. You can cut 1/4" or so of the end to a taper or start with a square end - it doesn't seem to make much difference in the appearance. Hold the end against the pipe, with tweezers if necessary, until you can get the tape wrapped at least partway around, and keep some tension on the tape as you wind. I overlapped each preceding wrap by about 1/3 or 1/2. When you come to the end, cut it off with your X-Acto blade.

I ended the first wrap at a point where the pipe goes through a mounting clamp on the smokebox front. The lower end will get lagging after the pipe is installed on the loco.

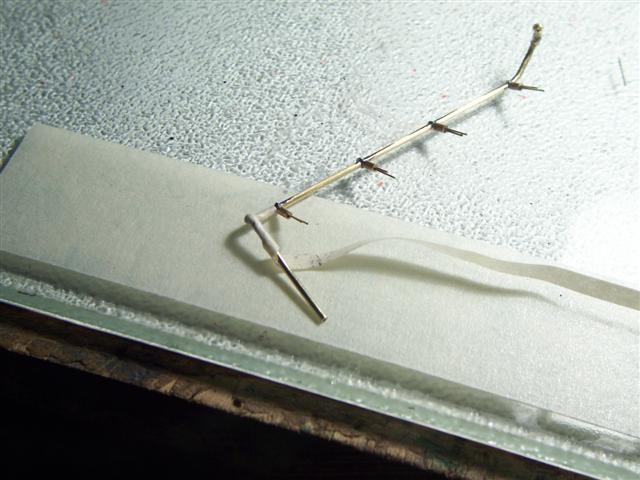

All of the other mounting clamps are installed on the pipe, along with stand-offs to keep the pipe in the proper position. The small wires protruding through the stand-offs will be inserted into holes in the boiler, then bent over to hold things in place.

When all of the lagging is in place, apply ca to all of it - all sides and especially the ends. Soak up any excess with tissue. The glue on the masking tape will eventually fail, but the ca will keep it in place. I have pipe that was lagged this way over 30 years ago that is still solid.

If you have areas to be lagged after installation, as I did, do so, then apply the ca as before.

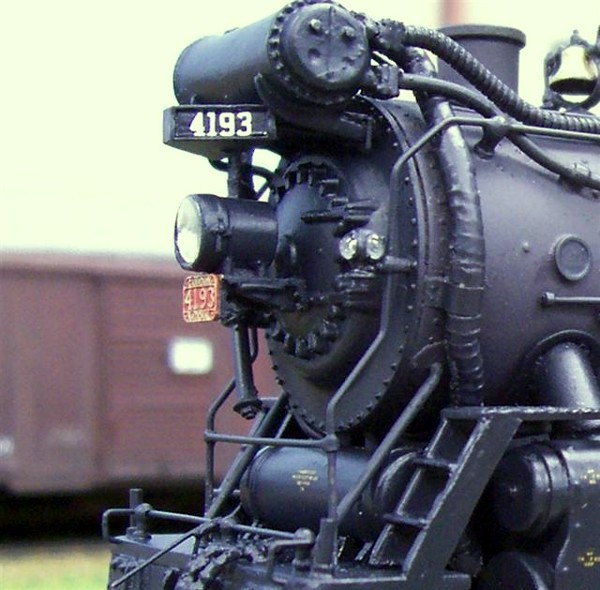

Here's a look at the installed pipe:

The front end has a simple plug, made from a large nbw casting. I drilled out the end of the wire, then ca'd the casting in place.

On the prototype, when the snow-loader was to be used, a hose would be attached to the end of this pipe, with the other end connected to the snow loader.

After you've installed the pipe, paint it using your usual paint and techniques. I brush-painted mine, using Floquil paint, as it was installed on an already painted loco.

And, on a different loco, some steam delivery pipes for an Elesco feedwater heater:

I hope that you'll find this simple technique useful.

Wayne

Rather than buying cast brass lagged pipe, you can make you own easily and at low cost, too. I made my pipe to represent a steam supply line for a Barber-Green Snow Loader.

First, fabricate the pipe from suitably-sized brass wire: use wire about two scale inches or so smaller in diameter than what you require for a finished size. The one shown below is .052", which is about 4 1/2" in HO. Make all of the necessary bends and determine the method that you'll be using to fasten it in place before starting the actual lagging procedure.

For lagging, stick a length of ordinary masking tape to a sheet of glass, then, using a new blade, trim off the factory edges and discard them. Next, measure and mark for the width of lagging that you want to use: for my large pipe, I made it 1'(HO) wide, and for the 4" (actual) length of the pipe, I used about 16" (actual) of tape.

Start at an end, or, as I did, at one of the mounting fixtures. You can cut 1/4" or so of the end to a taper or start with a square end - it doesn't seem to make much difference in the appearance. Hold the end against the pipe, with tweezers if necessary, until you can get the tape wrapped at least partway around, and keep some tension on the tape as you wind. I overlapped each preceding wrap by about 1/3 or 1/2. When you come to the end, cut it off with your X-Acto blade.

I ended the first wrap at a point where the pipe goes through a mounting clamp on the smokebox front. The lower end will get lagging after the pipe is installed on the loco.

All of the other mounting clamps are installed on the pipe, along with stand-offs to keep the pipe in the proper position. The small wires protruding through the stand-offs will be inserted into holes in the boiler, then bent over to hold things in place.

When all of the lagging is in place, apply ca to all of it - all sides and especially the ends. Soak up any excess with tissue. The glue on the masking tape will eventually fail, but the ca will keep it in place. I have pipe that was lagged this way over 30 years ago that is still solid.

If you have areas to be lagged after installation, as I did, do so, then apply the ca as before.

Here's a look at the installed pipe:

The front end has a simple plug, made from a large nbw casting. I drilled out the end of the wire, then ca'd the casting in place.

On the prototype, when the snow-loader was to be used, a hose would be attached to the end of this pipe, with the other end connected to the snow loader.

After you've installed the pipe, paint it using your usual paint and techniques. I brush-painted mine, using Floquil paint, as it was installed on an already painted loco.

And, on a different loco, some steam delivery pipes for an Elesco feedwater heater:

I hope that you'll find this simple technique useful.

Wayne

![[Image: gaugetraingifsigUP.gif]](http://i79.photobucket.com/albums/j137/wprm/gaugetraingifsigUP.gif)

![[Image: Barber-GreeneSnowloader.jpg]](http://i23.photobucket.com/albums/b399/doctorwayne/Scanned%20foe-toes/Barber-GreeneSnowloader.jpg)

, that lagged pipe really made a Fantastic addition to that steamer!

, that lagged pipe really made a Fantastic addition to that steamer! ![[Image: sig2.jpg]](http://i12.photobucket.com/albums/a246/lginc/vids/sig2.jpg)

![[Image: up_turb10k_r.gif]](http://i12.photobucket.com/albums/a246/lginc/vids/up_turb10k_r.gif)

![[Image: 3usra008.jpg]](http://i293.photobucket.com/albums/mm49/cnnutbar48/3usra008.jpg)