05-15-2010, 07:55 PM

All,

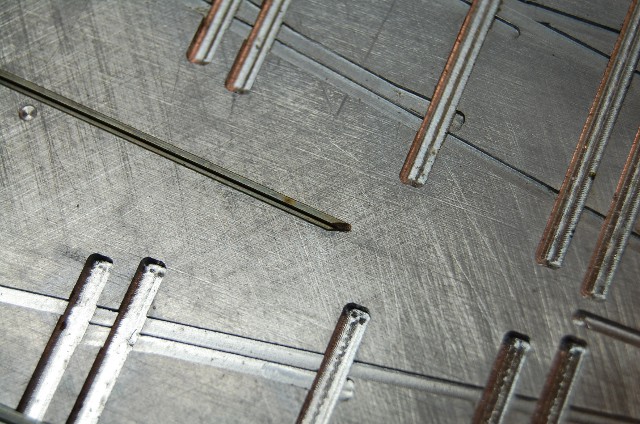

I've been having trouble with filing the points on the point form tool in that I tend to make the point end too thin, which makes it curl and / or require a lot of peeling / trimming of structurally insufficient metal.

I've recently had luck with pre-cutting an angle on the side that will be filed with a Dremel cut off tool - this seems to allow me to file down to a sharp point without working the metal too hard and causing the above. I also get to an effective point faster. Your mileage may vary, of course...

I've been having trouble with filing the points on the point form tool in that I tend to make the point end too thin, which makes it curl and / or require a lot of peeling / trimming of structurally insufficient metal.

I've recently had luck with pre-cutting an angle on the side that will be filed with a Dremel cut off tool - this seems to allow me to file down to a sharp point without working the metal too hard and causing the above. I also get to an effective point faster. Your mileage may vary, of course...

Matt Goodman

Columbus, Ohio

Columbus, Ohio