Posts: 1,548

Threads: 99

Joined: Jan 2012

I've used the "search" function on the forum but haven't really answered my problem .

On my HO layout-under-construction , I use code 100 Peco track and turnouts . I've recently removed the switch motors for a few reasons ....... would prefer manual control using knobs . The layout is 3'x10' for the first of two sections ( the second 3x10 will be built later ) and is point to point style .

The area of benchwork where I'd prefer to install the control knobs is about 6" LOWER than the turnouts I want to operate .

Any suggestions on how to go about doing this ?

Thanks , Terry

To err is human, to blame it on somebody else shows management potential.

Posts: 2,416

Threads: 63

Joined: Dec 2008

Terry:

How much distance do you have to go down the 6"?

Have you looked at the Bluepoint and Bullfrog (?) by Fastracks? They use flexible aeroplane tubing. I'm sure if you coiled it into a helix you could drop as required.

Or a lever pivoted 3" below the roadbed.

Or are you working an elevated section at the back? Then you get into aeroplane tubing with angle cranks and stuff.

David

Moderato ma non troppo

Perth & Exeter Railway Company

Esquesing & Chinguacousy Radial Railway

In model railroading, there are between six and two hundred ways of performing a given task.

Most modellers can get two of them to work.

Posts: 1,548

Threads: 99

Joined: Jan 2012

![[Image: gridwork006.jpg]](http://i1202.photobucket.com/albums/bb364/teejay1799/gridwork006.jpg)

The picture shows several turnouts just sitting in position , unfastened , as I configure the track . The plan would be to house the turnout control knobs in the grey coloured side rails of the benchwork . If the knob was situated in the middle of the 3" pine siderail , the distance vertically to the highest point of the trackwork is about 6" . It varies , depending on the turnout , between 5" and 6" .

I was thinking that if I could twist the knobs ( rather than push-pull ) , I could run a wire horizontally toward the turnout , have a vertical wire to the actual turnout , and join that 90 degree " angle " I'v created , with rubber tube . Not sure what mechanism would move the switch lever itself .

T

To err is human, to blame it on somebody else shows management potential.

Posts: 931

Threads: 68

Joined: Dec 2008

Not the cheapest way, but probably the easiest, for what you want to do <!-- m --><a class="postlink" href="http://www.sullivanproducts.com/GoldnRodMainFrame.htm">http://www.sullivanproducts.com/GoldnRodMainFrame.htm</a><!-- m -->

running a vertical wire - it will need fo be very stiff - over that length you will get flex, making movement/adjustment unpredictable. these are flexible and it should ne possible to run them directly to the turnouts, even around a curve - if youn are doing it as you describe, try brass electrical connectors (known in UK as choc-blocks) for joining the two rods, with twin screws that are cut from a strip - if you need more info on them, email me chacmool at lineone dot net

Posts: 9,748

Threads: 234

Joined: Dec 2008

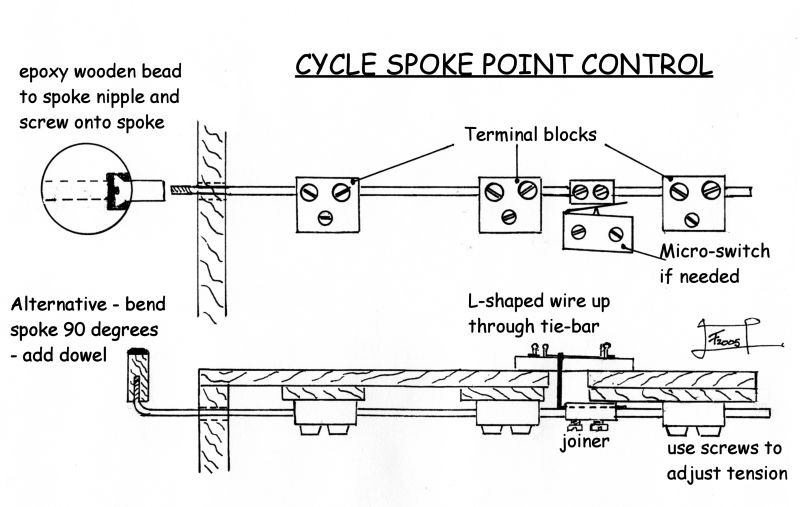

TeeJay, I just did this for about 50 cents a turnout. See the last few posts in my layout building thread and if you have any questions fire away

<!-- l --><a class="postlink-local" href="http://www.the-gauge.net/forum/viewtopic.php?f=46&t=2638">viewtopic.php?f=46&t=2638</a><!-- l -->

Charlie

Posts: 1,548

Threads: 99

Joined: Jan 2012

Geez Charlie , I even replied to that thread ....and promptly forgot about it .....brain fart I guess .

Thanks guys ,

T

To err is human, to blame it on somebody else shows management potential.

Posts: 4,553

Threads: 100

Joined: Dec 2008

teejay Wrote:Geez Charlie , I even replied to that thread ....and promptly forgot about it .....brain fart I guess .

I get a tingling sensation in my ears  when that happens, but it is almost imperceptible so I occasionally miss it

Just so you know, you're not alone. :oops:

We always learn far more from our own mistakes, than we will ever learn from another's advice.

The greatest place to live life, is on the sharp leading edge of a learning curve.

Lead me not into temptation.....I can find it myself!

Posts: 1,548

Threads: 99

Joined: Jan 2012

To err is human, to blame it on somebody else shows management potential.

Posts: 854

Threads: 52

Joined: Nov 2009

You could also use threaded rods to do so, see this video, made by a friend of mine, who uses this (his?) method on his layout.

<!-- m --><a class="postlink" href="http://www.youtube.com/watch?v=vidkCRwQB-E&feature=plcp">http://www.youtube.com/watch?v=vidkCRwQB-E&feature=plcp</a><!-- m -->

The other option you could use is the bolt lock system as Joe Fugate demonstrates in some of his videos (see the modeltrainsvideo website for details).

A link is here: <!-- m --><a class="postlink" href="http://model-trains-video.com/d-video-trackDCC.php">http://model-trains-video.com/d-video-trackDCC.php</a><!-- m -->

hope this helps.

Koos

Be sure to visit my model railroad blog at <!-- m --><a class="postlink" href="http://www.namrr.blogspot.com">http://www.namrr.blogspot.com</a><!-- m -->

Posts: 1,548

Threads: 99

Joined: Jan 2012

Thanks for the excellent advice , guys ....much appreciated . This is the only forum I'm active on so the advice here coupled with suggestions from 2 guys at work ( both accomplished mrrers ) has given me lots to chew on . Of course , there are pros and cons with all ideas . Money will have a significant bearing on my decision since I don't have much extra "hobby money " available .

The choices are : ....envelope , please

1. Just lean over the layout and activate the throw bars by hand . ( it's cheap  )

2. Use my existing Peco switches ( they're noisy and require a 1.5" x .75 " hole which I don't like )

3. Modify the Peco switch mounting to a spot under the benchwork , requiring only a small hole up to the throwbar .

4.Use Caboose Industry ground throws ( not a bad looking product especially if I go with N scale throws ....but $5-6 each :evil: )

5.Use one or more of the suggestions provided above by forum members .

6.Find another switch machine product ( under the layout style ) at a train sale .

...decisions, decisions .

Terry

To err is human, to blame it on somebody else shows management potential.

Posts: 931

Threads: 68

Joined: Dec 2008

Terry - an old cycle wheel and some choc-blocks will do this - cost choc-blox and some screws

Posts: 2,416

Threads: 63

Joined: Dec 2008

Terry:

I have a bunch of Peco machines mounted under the Homasote. Some Peco motors came with an extension for the wire. This is a brass tube and another bit of wire. You can use some tube & wire from the LHS. I crimped the tube so that it didn't move much in the direction of throw. I also bent the mounting pins out and fastened the motor with a couple of #8 screws with washer heads. neat trick: drill down just beyond the throw bar on the switch and you have the right place to mount the motor (HO gauge only). You then need only to have frilled a 1/4" (or a bit more) hole right under the hole in the tiebar.

There used to be a kit for mounting the motor. This had a bit of tube that went right under the throwbar and a brass pin that came down from the top.

David

Moderato ma non troppo

Perth & Exeter Railway Company

Esquesing & Chinguacousy Radial Railway

In model railroading, there are between six and two hundred ways of performing a given task.

Most modellers can get two of them to work.

Posts: 1,229

Threads: 23

Joined: Dec 2008

Quote:I was thinking that if I could twist the knobs ( rather than push-pull ) , I could run a wire horizontally toward the turnout , have a vertical wire to the actual turnout , and join that 90 degree " angle " I'v created , with rubber tube . Not sure what mechanism would move the switch lever itself .

I wrote an article about this very subject:

<!-- m --><a class="postlink" href="http://model-railroad-hobbyist.com/magazine/mrh-2011-Feb/turnout_controls">http://model-railroad-hobbyist.com/maga ... t_controls</a><!-- m -->

If you want a MUCH more DIY approach, but a similar rotary motion, Charlie Comstock wrote an article in MRH Q2 (April) 2009, on pg. 59.

Both are Forever FREE and available for download.

Galen

I may not be a rivet counter, but I sure do like rivets!

Posts: 1,548

Threads: 99

Joined: Jan 2012

Thanks Galen , I've saved your article ...I'll look for the other one .

David , I checked the three unopened Peco switch motor I still have on the wall ....no enclosed extension rod .....but as you say , I should be able to rig something up if I go that way . I'm even thinking of just having the turnouts at the back of the layout powered and having the closer ones manual . I haven't decided yet .

Thanks again , all .

Terry

To err is human, to blame it on somebody else shows management potential.

|

![[Image: gridwork006.jpg]](http://i1202.photobucket.com/albums/bb364/teejay1799/gridwork006.jpg)

when that happens, but it is almost imperceptible so I occasionally miss it

when that happens, but it is almost imperceptible so I occasionally miss it