02-05-2013, 05:53 PM

Well Sumpter I never looked into the 'why' only that it is there. But , the cast water bottom sounds plausible to me. Thanks for the input.

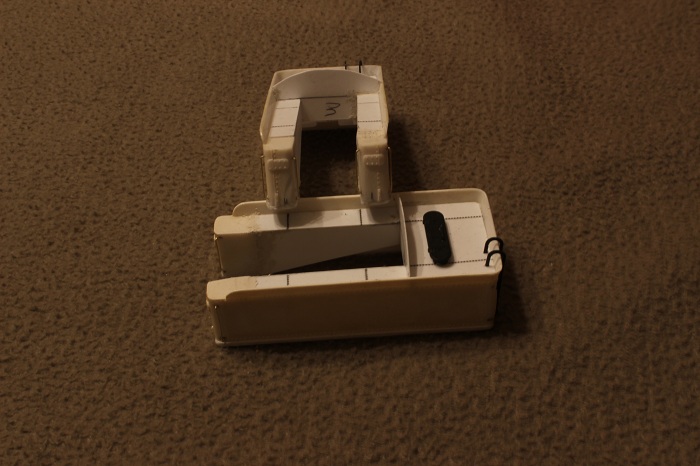

I started on the Coal bunkers yesterday. If you look at the picture of the one on left you can see the support that holds the tender shell to the frame.

I have filled in some of the gaps with squadron putty that will have to be sanded down.

The bottom of the bunker will remain open and will be covered with some foam shaped to the contours of the coal load. I have decided to completely remove the harness that are for the DCC plugs and replace it with just a single two wire plug. I post pics of that tomorrow.

I started on the Coal bunkers yesterday. If you look at the picture of the one on left you can see the support that holds the tender shell to the frame.

I have filled in some of the gaps with squadron putty that will have to be sanded down.

The bottom of the bunker will remain open and will be covered with some foam shaped to the contours of the coal load. I have decided to completely remove the harness that are for the DCC plugs and replace it with just a single two wire plug. I post pics of that tomorrow.

My other car is a locomotive, ARHS restoration crew

, but it started to snow just as I got home from work. So I'll post what I've been up too.

, but it started to snow just as I got home from work. So I'll post what I've been up too.